Quick Email Now!

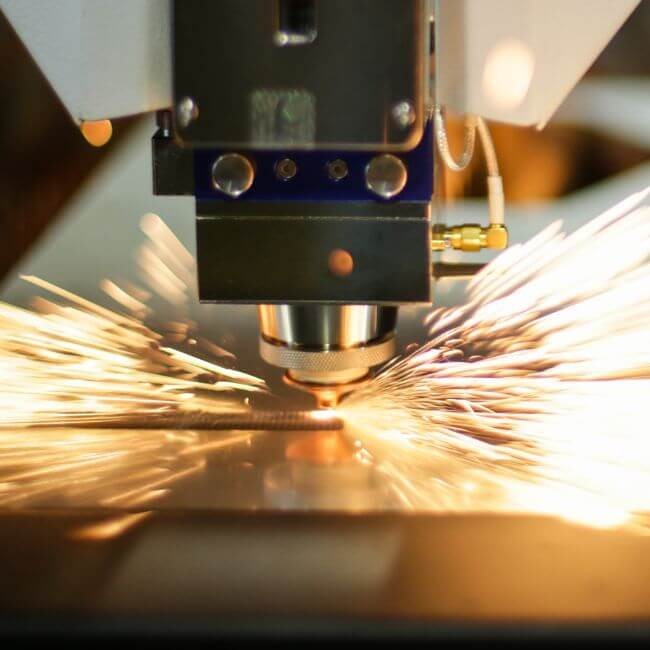

Laser cutting is a process that involves vaporising the material to be cut using a laser, which ultimately results in a cut edge at the end of the process. Despite the fact that its most common applications are in manufacturing and industrial work, it is also used in some commercial settings. In order to perform laser cutting, the output of a high-power laser needs to be steered, and this is typically accomplished through the application of optics.

During this process, laser optics and CNC, also known as computer numerical control, are being utilised in order to precisely direct the laser beam at the material to be processed. When cutting materials with a commercial laser, a motion control system is used so that the laser can follow a CNC or G-code that specifies the pattern that should be sliced into the material. This ensures that the laser cuts the material according to the desired pattern. A highly concentrated beam of laser light is used to direct the material, which then either melts, burns, vaporises, or is driven away by a jet of gas, leaving behind an edge with a surface finish of a very high grade.

We provide our services to a variety of industries, including the ones that deal in automotive components, agricultural components, earth moving and construction equipment, railways, the renewable energy sector, industrial components, and so on.

Get in touch with us if you have any specific requirements.

Benefits of Laser Cutting:

- Precision Beyond Imagination

- No Taper Cutting Hurdle

- Time Saving

- Fine Cutting Edges

- Easily & Accurately Repeatable

- Cutting Narrow Kerf Width

- Less Heat Affected Zone

- Reduction In Set Up Time

- Machining/Drilling Operation Can Be Avoid

- Just In Time Availability

- Can Almost Save Machining Cost By Laser Cutting

- Holes On Plates Lower Than Its Thickness On New 2 Kw Laser Technology